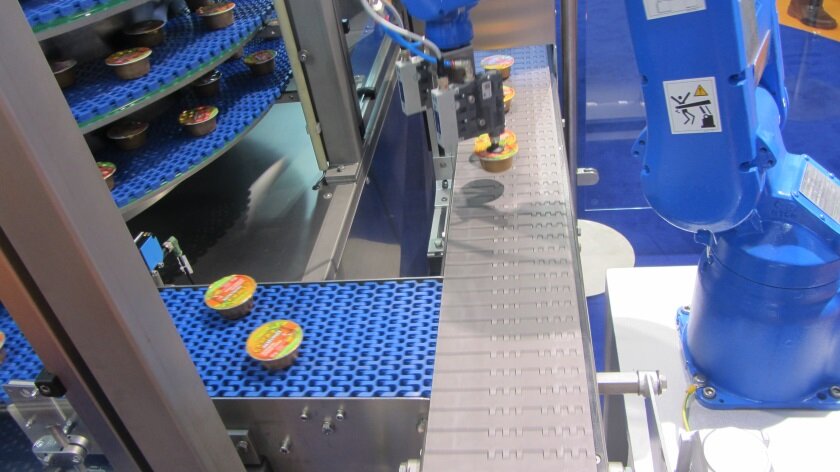

Gronemeyer Pick & Place

- Industrie

- Settore Alimentare

- Applicazioni

- Pick & Place

- Material Handling

- Client

- Gronemeyer Maschinenfabrik GmbH & Co. KG

Challenge

- Many products are filled using high-performance systems and then require cooling

- As they are to spend as long as possible in the cooling cell, they are transported through the cooling spiral in multiple lanes

Solution

- The products are detected on the feed conveyor to the cooling system by means of a camera system

- This signals the position to the Motoman Picker, which then picks up the products accordingly and sets them down in two rows on the chain of the cooling tunnel

- The option of setting the products back down with an offset means that the conveyor can be used more effectively

- The airflow and thus the cooling effect is optimized in this way

Result

- Energy-efficient solution with small footprint and fast adaptability for product changes